Mercedes' high-voltage (HV) systems, vital for modern vehicle safety and performance, require specialized tools like the Mercedes High-Voltage Disconnect (HVD) for maintenance. Correct HVD utilization, alongside proper training and best practices, ensures safe repairs for auto body restoration and car scratch repair professionals, protecting them from electrical risks while preserving vehicle reliability.

Mercedes high-voltage systems power a wide range of modern vehicle components, from electric motors to advanced driver assistance systems. Given their complexity and potential hazards, safe servicing requires a crucial step: the Mercedes high-voltage disconnect (HVD). This safety mechanism isolates high-voltage circuits, minimizing risks associated with electrical shocks or arcing during maintenance. Understanding the HVD’s role is essential for technicians ensuring both worker safety and optimal vehicle performance.

- Understanding Mercedes High-Voltage Systems

- The Role of High-Voltage Disconnect in Safety and Service

- Best Practices for Safe and Effective Servicing

Understanding Mercedes High-Voltage Systems

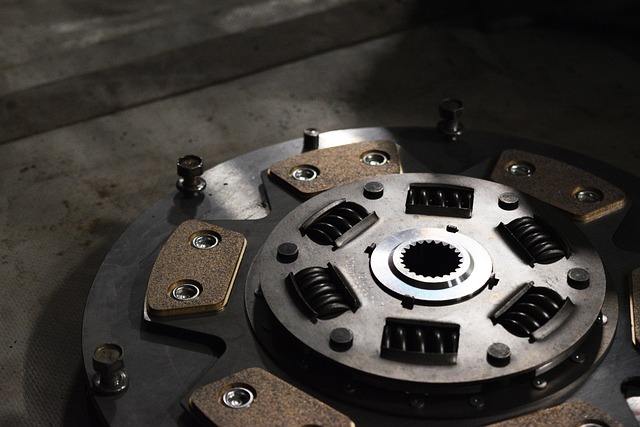

Mercedes high-voltage systems are a complex network of components designed to power modern vehicles’ advanced electrical systems. These systems play a critical role in enhancing safety, efficiency, and overall performance. From electric motors and battery packs to sophisticated infotainment and driver assistance features, the high-voltage (HV) architecture in Mercedes cars is a marvel of engineering. Understanding these systems is essential when considering any form of maintenance or repair, especially as they differ significantly from traditional 12-volt electrical setups.

The integration of HV technology in automobiles requires specialized tools and procedures to ensure safety during servicing. One such critical component is the Mercedes high-voltage disconnect (HVD). This innovative feature allows technicians to safely isolate the HV system from the rest of the vehicle, facilitating repair or replacement without exposing the operator or equipment to high-voltage risks. Effective management of these systems, through proper training and tools like the HVD, is vital for professionals in the auto body restoration and car scratch repair sectors, ensuring that repairs are not only efficient but also secure.

The Role of High-Voltage Disconnect in Safety and Service

The Mercedes high-voltage disconnect (HVD) plays a pivotal role in both safety and service procedures for modern vehicles. In the realm of automotive repair, particularly with luxury cars like Mercedes, the HVD acts as a crucial safety mechanism by isolating the high-voltage electrical system during servicing or maintenance work. This isolation prevents accidental electrocution or severe shocks, ensuring the well-being of technicians and customers alike.

Moreover, for auto detailing or car body repair professionals, understanding and correctly handling the Mercedes high-voltage disconnect is essential. It allows them to safely navigate complex electrical systems, enabling precise repairs without causing damage to sensitive components. This meticulous approach not only enhances the quality of service but also prolongs the life of the vehicle, demonstrating the importance of proper training in automotive repair practices.

Best Practices for Safe and Effective Servicing

When undertaking any servicing on a Mercedes vehicle, especially those equipped with high-voltage systems, following best practices for safe and effective procedures is paramount. The first step involves engaging the Mercedes high-voltage disconnect mechanism. This crucial safety measure isolates the high-voltage components from the rest of the electrical system, ensuring that work can be performed without risk of electrocution or damage to sensitive parts. By doing so, technicians can confidently proceed with tasks such as fender repair or collision repair, which are integral parts of auto bodywork services.

Proper handling of high-voltage systems requires specialized knowledge and tools. Technicians should always use appropriate personal protective equipment (PPE) to shield against electrical hazards. Additionally, working in a well-lit, organized area with easy access to necessary tools facilitates efficient and safe servicing. Remember, adhering to these best practices not only safeguards the technician but also ensures the longevity and reliability of the vehicle’s high-voltage components, such as those found in modern electric or hybrid vehicles, after completion of auto bodywork repairs.

Mercedes high-voltage systems, with their advanced capabilities, require a meticulous approach during servicing. The implementation of a high-voltage disconnect is not just a safety measure; it’s an indispensable step that ensures the integrity of these intricate systems. By isolating high-voltage components, technicians can work with confidence, knowing they’re protected from unexpected discharges. This safe and structured process is key to maintaining Mercedes’ reputation for innovation and performance, while also guarding against potential hazards. Thus, a thorough understanding of, and adherence to, best practices involving Mercedes high-voltage disconnect, is paramount for any service provider.